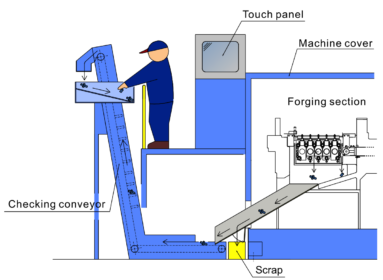

・The blank can be checked immediately on the operator platform during test runs and cutoff adjustments.

・It won’t be necessary to get down from the operator platform in order to check the blank, which will significantly reduce work time.

Solution

Improve Operation

Because a maximum of 512 kinds of product information can be managed, it is suitable for customers who will be running production of many products on 1 former.

Before improvement

・Adjustment work after the product is selected takes time.

・Because product registration and tooling management are done on paper, it’s difficult to keep oil from getting on these documents.

・The operation takes time even for experienced operators.

・Adjustment work after the product is selected takes time.

・Because product registration and tooling management are done on paper, it’s difficult to keep oil from getting on these documents.

・The operation takes time even for experienced operators.

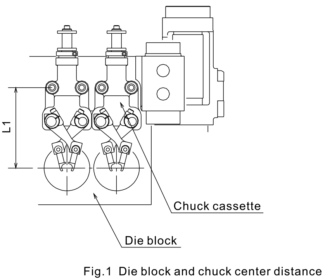

The dimensions of the center L1 between the chuck and the die block will change as a result of factors such as wear on the top of the die block and wear on the bottom of the chuck from many years of use.

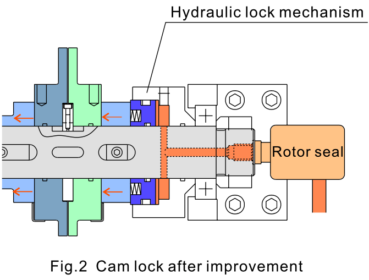

The hydraulic lock system releases and locks with just one button. Work can be significantly improved and time can be saved in adjusting the chuck open/close timing.

The punch position’s digital display system (ATP monitor)is a system that displays the position of the punch’s X direction(horizontal)and Y direction(vertical)digitally to a unit of 0.01mm.(PAT.H4-60339)

The adjustment of the punch’s front dead point position requires skill. A mechanical counter is installed on each station and by changing the punch’s front/back position digitally, the adjustment time can be shortened.

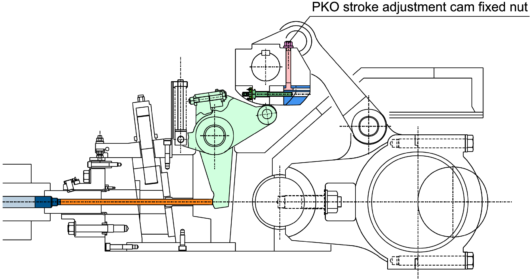

Normally, modification of the PKO stroke is performed by replacing the PKO cam.

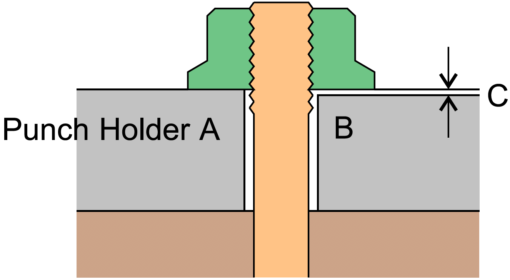

Normally the punch holder is fit together by a nut, but in the case of larger machines, tightening and loosening this nut with a 2m torque wrench requires a great amount of force.

Before reconstruction

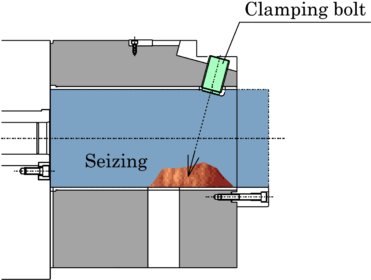

・It takes great force to tighten the clamping bolt enough so that it won’t loosen. Also, the point where the lower side of the die and the die block hole connects seizes easily.

・It takes great force to tighten the clamping bolt enough so that it won’t loosen. Also, the point where the lower side of the die and the die block hole connects seizes easily.

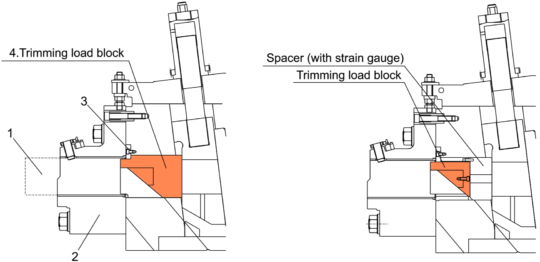

The trimming load block can be replaced without removing the punch holder.

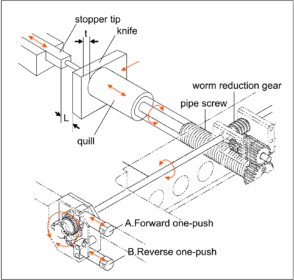

To achieve a beautiful cutoff surface with no steps, there needs to be moderate clearance between the knife and the quill.

During tooling replacement the ram is stopped at the back dead point, but with the timing of the ram’s position the pusher has advanced into the cutoff knife so knife replacement can’t be done.

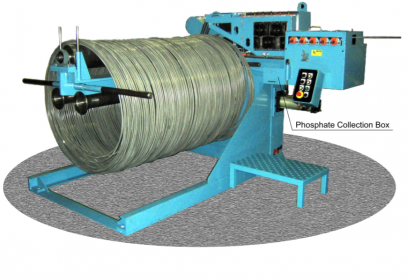

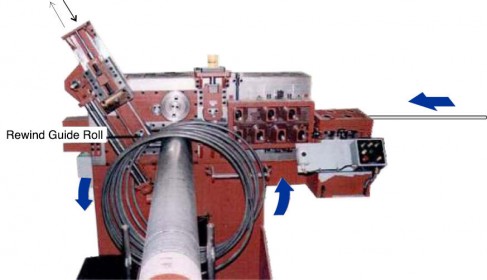

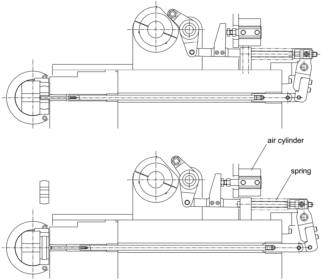

Material replacement, material pullout, wire straightening, feed roll replacement…

These processes usually account for half of the changeover time. This can especially be seen in large machines, as the feed roll change requires a lot of work.

These processes usually account for half of the changeover time. This can especially be seen in large machines, as the feed roll change requires a lot of work.

The coil material is formed into a straight line and supplied to the former. When the material or the diameter of the material changes, adjustments need to be made. By providing a mechanical counter for positioning the wire straightener roll and based on the value of the counter when the material’s diameter is changed, accurate reproduction can occur. Conventionally, the positioning is reproduced by using a scale and indicator, but by changing to digital, this can be done much quicker.