Solution

Enhanced Safety

Oil mist adversely affects the air, temperature, and visual environment in the work place. If oil mist is not removed, environmental and health issues will develop.

In order to improve safety, there has been a change from a single valve (three-way poppet type) to a double valve.

In a former, there are situations in which work needs to be completed in the forging area, such as punch adjustments. Performing work in an unstable area like this can be dangerous.

A protective cover has become necessary in order to prevent injuries that are caused when jogging to make adjustments.

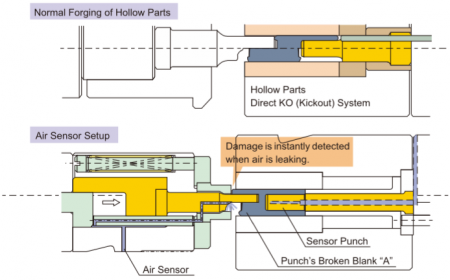

If the punch for the front and back extrusion of hollow parts is broken, it will be transferred to the next station and accidents can occur.