Technology Information

Quick Changeover/Operational Efficiency

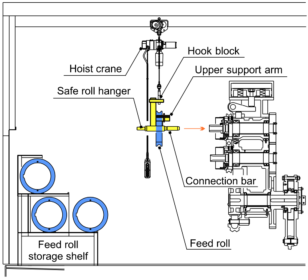

When installing/removing the feed roll, you have to lift the heavy roll to a high position, which is extremely difficult, especially for larger machines. In addition, if dropped accidentally, not only could feed roll damage occur, but the operator could be seriously injured.

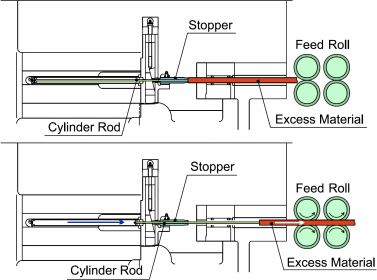

If the former stops while bar-material is being supplied, material may remain inside of the machine.

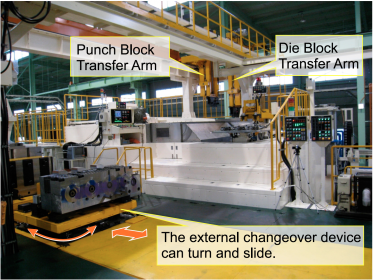

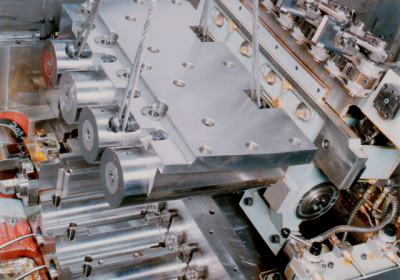

The ATBC (Auto Tool Block Changer) robot removes the die/punch hydraulic lock system, and the die and punch block are changed automatically in five minutes.

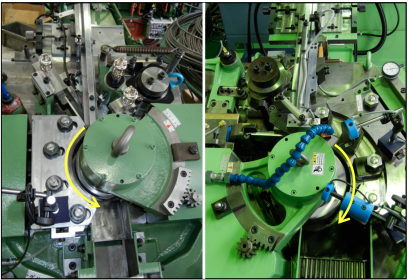

Based on the customer’s request, the rotary rolling machine can rotate clockwise or counter-clockwise.

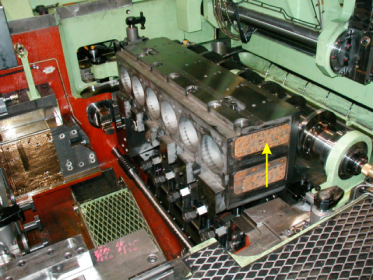

In large machines, there are die blocks (with the dies set) that exceed more than two tons.

When removing or setting a die block in the frame, a crane is usually used, but positioning a swinging die block during transport can be difficult. In addition, it is possible for the frame to be damaged by the swinging die block.

In a long former, naturally the die is also longer, making it difficult to detach. It is hard work to remove a long die from the die block.

By placing the trimming rod on the cutter side, access to the forging area has become easier.

Adjustments are made in conventional formers by the clutch jogging system, which uses manual buttons.

After the transfer moves upward, it swings 90° and turns toward the operator side.

Since the entire chuck has the ability to turn, the operator can safely change chuck fingers or make adjustments to the center of the machine without having to enter it.