Technology Information

Stable Operation

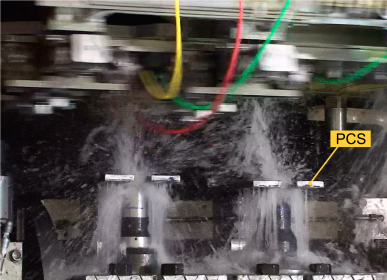

On hot formers, it is necessary for the punch to be sprayed evenly with cooling water.

With the PCS, coolant water is applied to the punch from the front. This allows for the entire punch to be cooled evenly, and a longer tooling life can be expected.

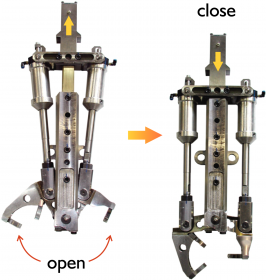

The TF-type chuck holds the blank at three points, allowing for products of any shape to be gripped for stable transfer.

The SSR rotary rolling machine can be aligned with the former.

Generally, parts that are dispatched from the former are supplied to the rolling machine via a slide conveyor or parts feeder, but there are some cases in which a pipe chute is adopted.

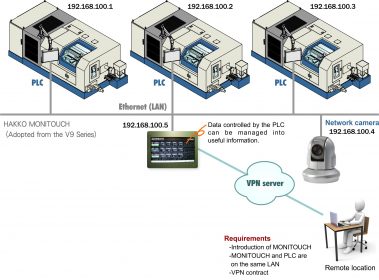

The condition of factory equipment can be monitored from headquarters, and by checking for signs of abnormalities, scheduled maintenance of machines can be implemented.

VNC (Virtual Network Computing) is remote desktop software that can control a different computer’s screen (that is connected to the same network).

Using this software, you can check and operate a touch panel screen from a remote location.

Using this software, you can check and operate a touch panel screen from a remote location.

If an electrician is unable to travel or if a customer is overseas, the same work can be performed as if they were on-site. This is possible by connecting a computer to your device. Once the remote software is launched, your computer can be accessed remotely through the internet.

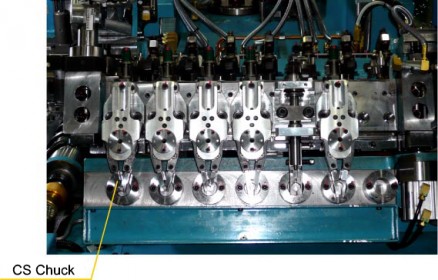

The CS chuck is a cassette-type chuck that can be set at any station. Because the chuck fingers rise and open wide, the open upset diameter and chuck clear diameter can be set larger than the conventional type.

When the transfer has a blank that is an abnormal shape, the PFAS assists by ensuring that the blank is transported to the next station. This can even be done during high speed operation.