Classification Due to Temperature Range

Different temperature ranges are used when forging, depending on the properties and shape of the piece to be worked on. Depending on the temperature, there is cold, warm, and hot forging.

Formers used in cold forging are called, “cold formers.” Warm forging formers are called “warm formers,” and hot forging uses “hot formers.”

Formers used in cold forging are called, “cold formers.” Warm forging formers are called “warm formers,” and hot forging uses “hot formers.”

Cold Forging

”Cold forging” is a process done at room temperature, in which a heating device (not a cooling device) is used.

The coolant oil that is supplied to tools and products in processes such as extrusion and piercing does not have a large limit on the amount of additives used.

When processing at room temperature, although resistance to deformation is high, dimensional accuracy and near-net-shaping are possible.

”Cold forging” is a process done at room temperature, in which a heating device (not a cooling device) is used.

The coolant oil that is supplied to tools and products in processes such as extrusion and piercing does not have a large limit on the amount of additives used.

When processing at room temperature, although resistance to deformation is high, dimensional accuracy and near-net-shaping are possible.

Warm Forging

In warm forging, a heating device is required to heat products to a temperature ranging from 300 to 800 degrees Celsius.

The temperature will differ depending on the “material’s properties” and the “desired shape.” However, depending on the temperature, different heating devices, such as resistance or induction heaters, are used.

If a material’s heating temperature is high, cooling measures must be administered to machine parts or mechanisms that have come in contact with the heated material.

In warm forging, a heating device is required to heat products to a temperature ranging from 300 to 800 degrees Celsius.

The temperature will differ depending on the “material’s properties” and the “desired shape.” However, depending on the temperature, different heating devices, such as resistance or induction heaters, are used.

If a material’s heating temperature is high, cooling measures must be administered to machine parts or mechanisms that have come in contact with the heated material.

Hot Forging

In hot forging, the temperature range is typically 1,000 to 1,500 degrees Celsius.

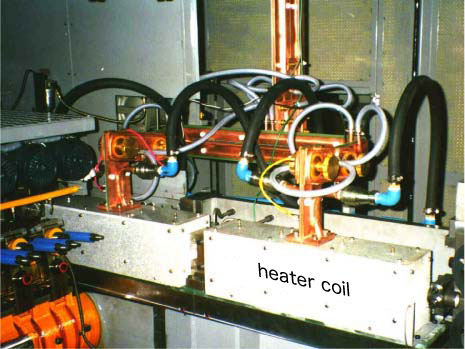

A high frequency induction heating device is generally used.

A coolant (that was cooled by external cooling equipment) is circulated through each mechanism including the material feeding section, the material guide section, and the forging section. The coolant is composed of “high cooling capacity water” in which a corrosion inhibitor has been added.

When the raw material is heated at an extremely high temperature, resistance to deformation decreases.

In hot forging, the temperature range is typically 1,000 to 1,500 degrees Celsius.

A high frequency induction heating device is generally used.

A coolant (that was cooled by external cooling equipment) is circulated through each mechanism including the material feeding section, the material guide section, and the forging section. The coolant is composed of “high cooling capacity water” in which a corrosion inhibitor has been added.

When the raw material is heated at an extremely high temperature, resistance to deformation decreases.

Various factors must be considered when deciding the forging temperature such as the size of the desired product, the type of material, the material’s resistance to deformation and deformability, equipment limitations, production quantity, cost comparison of competing processes, etc.

Technology Information:About Formers